Our Machinery

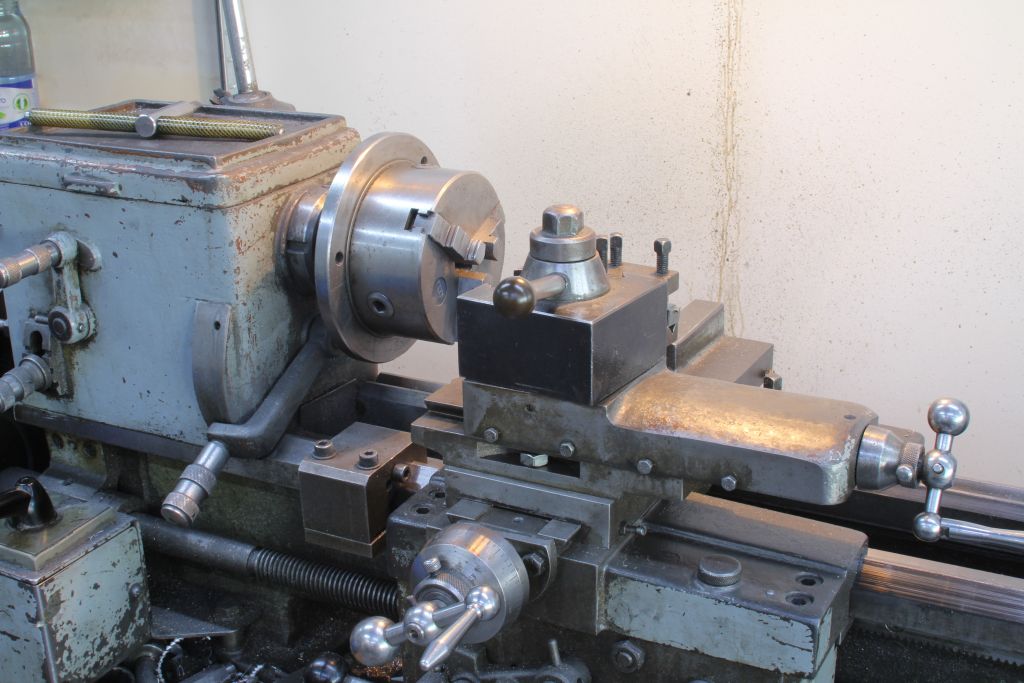

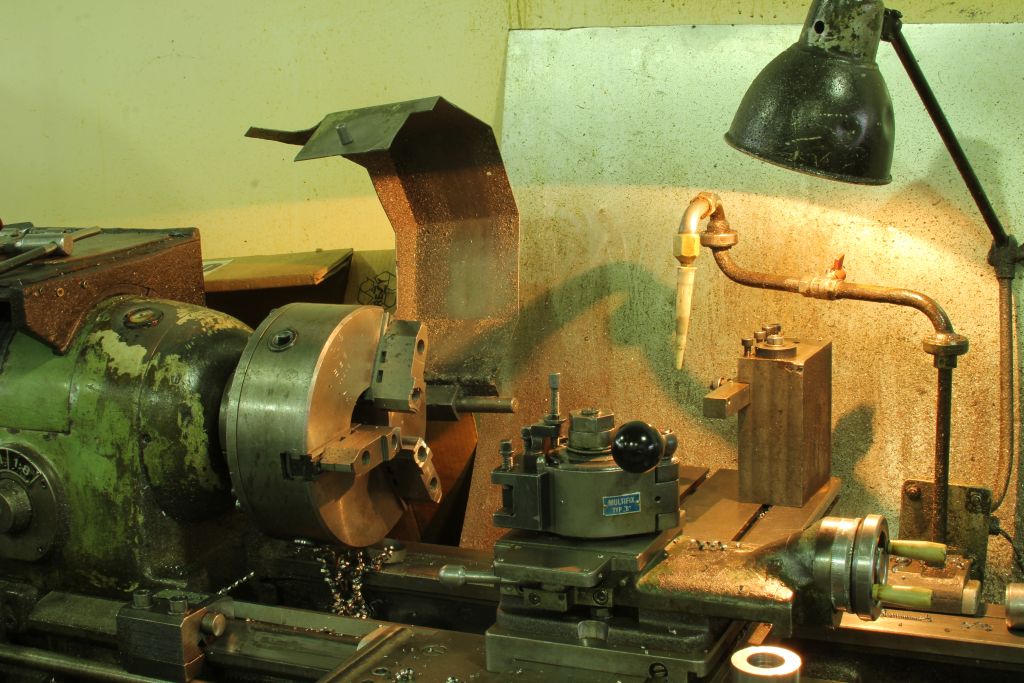

On our lathes we can machine bar stock from Ø6 to Ø42 mm, but on the SLT-240 and the Spinner TC400 C-axis machines we can also machine Ø51 mm bar stock in a chuck, while our Y-axis, counter-spindle turning center has a maximum bar capacity of Ø65 mm.

In “flying” (unsupported) machining, we typically work with 3×D to 5×D overhang. Larger-diameter materials are cut in-house with our band saw or ordered pre-cut, allowing us to turn chucked parts up to Ø200 (Ø250) mm. For small quantities, machining is economical down to Ø2 mm.

Our CNC milling machine has a working area of 760 × 380 mm. The Z-stroke is 150 mm, and the table height can be adjusted as a W-axis. Our milling capacity has been expanded with the acquisition of a Spinner machining center. In addition to our HunCut program, Edgecam CAM software now also supports the production of custom, small-batch and even 3D parts.

CNC Machining Center

CNC Turning Center

CNC Lathes

Siemens 810D, C-axis, driven tools, hydraulic tailstock, bar feeder, part catcher

Fanuc 18i-T, C-axis, driven tools, hydraulic tailstock, bar feeder, part catcher, chip conveyor

CNC Milling

Measuring Equipment

Turning

Conventional universal lathes:

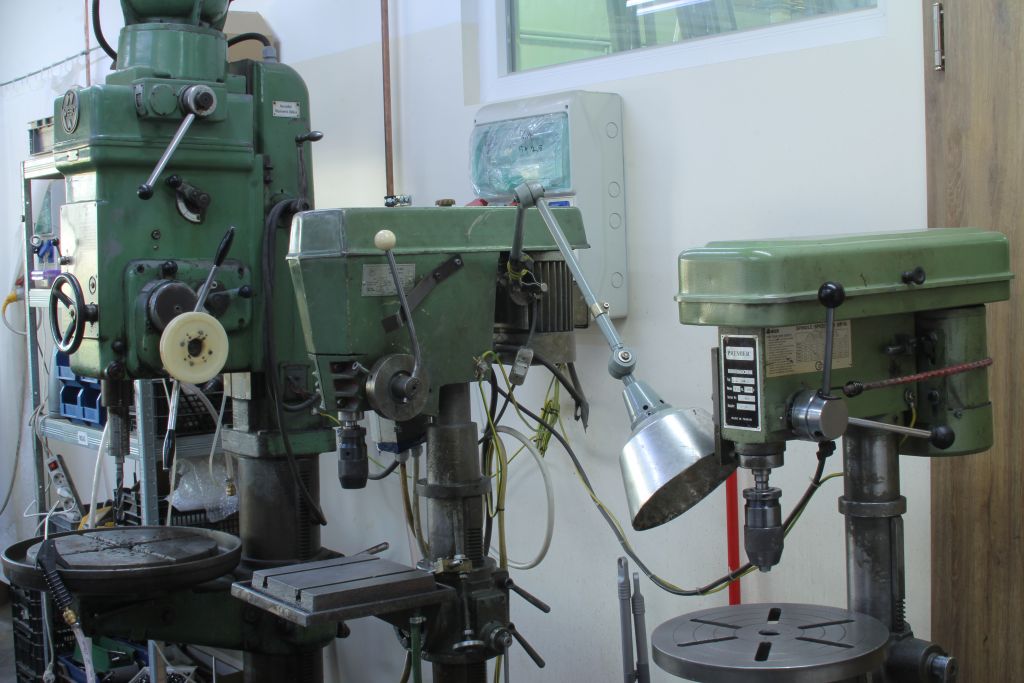

Milling:

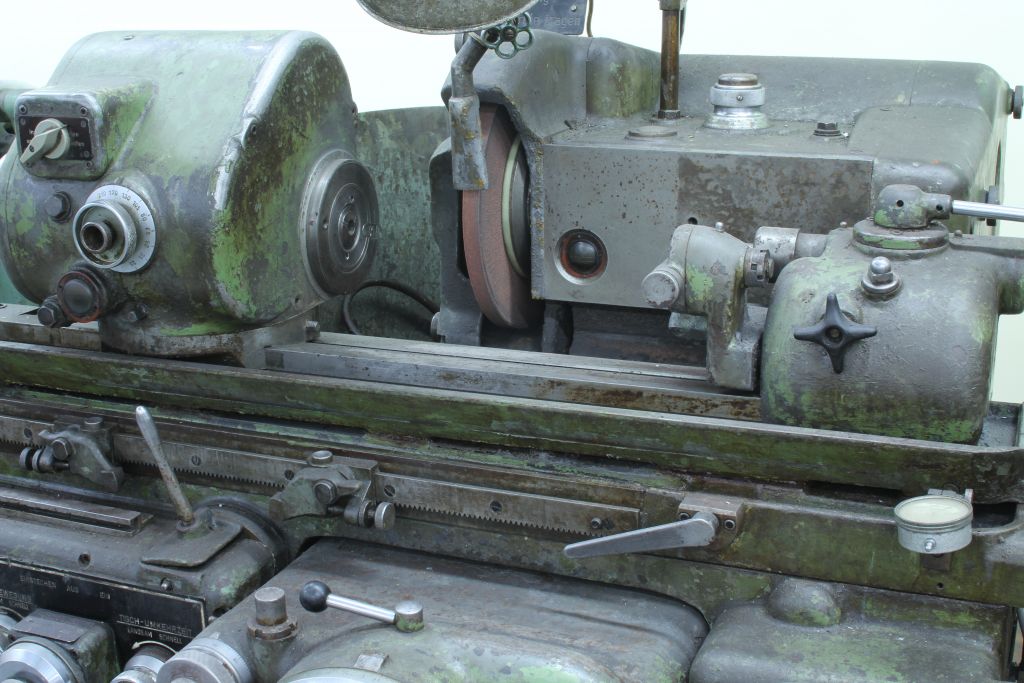

Grinding:

Other Equipment:

We also have all the smaller machines required for toolmaking and general workshop work, such as cutting and drilling machines:

Video: Machine Deburring